Feel this form get brochure

Enquiry Now

Feel Free To Ask Anything

MEWAR HITECH ENGINEERING LTD

MANUFACTURER OF CRUSHING SCREENING AND SIZE REDUCTION EQUIPMENT

MEWAR HITECH ENGINEERING LTD

MANUFACTURER OF CRUSHING SCREENING AND SIZE REDUCTION EQUIPMENT

MEWAR HITECH ENGINEERING LTD

MANUFACTURER OF CRUSHING SCREENING AND SIZE REDUCTION EQUIPMENT

MEWAR HITECH ENGINEERING LTD

MANUFACTURER OF CRUSHING SCREENING AND SIZE REDUCTION EQUIPMENT

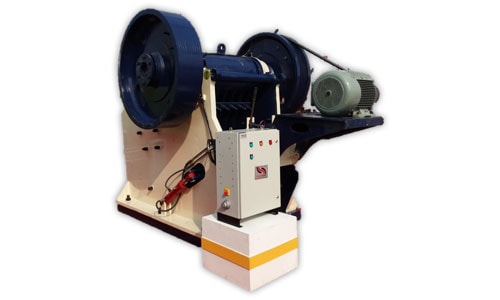

Single Toggle Grease Jaw Crusher

Kingson’s Single Toggle Grease Jaw Crusher is usually utilized where size conveyance isn't of fundamental significance, be that as it may, efficiency is to be increased with lower power utilization, in contrast with Double Toggle Grease Lubricated Jaw Crusher and hence working expense is lower. These do not require high operating skills and gap setting is easier and manageable. Additionally, the support necessity is much lower and it doesn’t require high maintenance.

Key Features:

● Increased stroke for greater productivity, large eccentric shaft for strong stroke in the upper chamber.

● High angle toggle plate increases stroke in the lower chamber.

● The large precise counter balanced flywheel provides continuous crushing in toughest applications.

● Stress relieved, robust, heavy duty crusher body and cast steel jaw plates for higher strength.

● In case of use as primary crusher, a hydraulic cylinder is provided for easy adjustment of gap setting.

| S.NO. | JAW CRUSHER SIZE | RECOMMENDED | CAPACITY IN TONS / HOUR WITH JAW CLOSED SIDE SETTING | RPM | DRIVE HP | APPROX TOTAL WT.(TON) | |||||||||||||||||

| INCH | MM | feed (mm) | size (inch) | 20MM | 25MM | 31MM | 37MM | 50MM | 62MM | 75MM | 87MM | 100MM | 125MM | 150MM | 175MM | 200MM | 225MM | 150MM | 175MM | ||||

| 0.25" | 1" | 1.25" | 1.50" | 2.00" | 2.50" | 3.00" | 3.50" | 4" | 5" | 6" | 7" | 8" | 9" | 10" | 11" | ||||||||

| PRIMARY CRUSHER | |||||||||||||||||||||||

| 1 | 20"X10" | 500x250 | 175 | 7 | 27 | 31 | 39 | 47 | 320-340 | 30 | 4.06 | ||||||||||||

| 2 | 24"X12" | 600X300 | 225 | 9 | |||||||||||||||||||

| 3 | 24"X18" | 600x450 | 375 | 15 | 28 | 37 | 46 | 56 | 65 | 300-320 | 50 | 6.7 | |||||||||||

| 4 | 30"X15" | 750x375 | 300 | 12 | 46 | 58 | 70 | 81 | 93 | 300-320 | 60 | 7.85 | |||||||||||

| 5 | 30"X20" | 750x500 | 425 | 17 | 70 | 81 | 93 | 116 | 139 | 300-320 | 75 | 10.1 | |||||||||||

| 30"X24" | 750X600 | 525 | 21 | ||||||||||||||||||||

| 6 | 36"X24" | 900x600 | 525 | 21 | 112 | 139 | 167 | 195 | 260-280 | 100 | 18.27 | ||||||||||||

| 36"X30" | 900X750 | 675 | 27 | ||||||||||||||||||||

| 7 | 42"X32" | 1050x800 | 675 | 27 | 130 | 162 | 195 | 228 | 255 | 240-260 | 150 | 21.5 | |||||||||||

| 8 | 42"X36" | 1050x900 | 800 | 32 | 130 | 162 | 195 | 228 | 255 | 287 | 240-260 | 175 | 24 | ||||||||||

| 9 | 48"X36" | 1200x900 | 800 | 32 | 185 | 220 | 260 | 290 | 325 | 240-260 | 200 | 34.53 | |||||||||||

| 10 | 60"X48" | 1500x1200 | 1100 | 44 | 325 | 361 | 405 | 444 | 500 | 180-200 | 325 | 80 | |||||||||||

| SECONDARY CRUSHER | |||||||||||||||||||||||

| 10 | 36"X08" | 900x200 | 175 | 7 | 21 | 26 | 33 | 39 | 52 | 320-340 | 50 | 6.5 | |||||||||||

| 11 | 42"X09" | 1050x225 | 200 | 8 | 25 | 31 | 39 | 46 | 61 | 320-340 | 60 | 7.1 | |||||||||||

| 12 | 48"X09" | 1200x225 | 200 | 8 | 28 | 35 | 44 | 52 | 69 | 320-340 | 75 | 10.5 | |||||||||||